Medical

Medical Device Development

At Formero, we are dedicated to supporting our clients in every step of medical device development. With our wide range of advanced technologies and expertise, we provide comprehensive solutions to transform your medical device concepts into reality. From concept presentation models to prototype development, short-run manufacturing, and production, our capabilities ensure the highest quality and efficiency throughout the entire product development process.

Stage 1: Concept or Presentation Models

During the initial stages of medical device development, we offer a variety of technologies to create concept or presentation models. CNC Machining, SLA (Stereolithography), and DLP (Digital Light Processing) technologies allow for precise and detailed models that accurately represent your design concepts. We have had the privilege of working with industry leaders like ResMed, a global leader in sleep technology, to create presentation models that showcase their innovative solutions and drive their success.

Stage 2: Prototype Development

Moving from concepts to functional prototypes, our advanced technologies come into play. Our DLP, FFF (Fused Filament Fabrication), and CNC Machining capabilities enable the development of functional prototypes that undergo rigorous testing and evaluation. These prototypes provide valuable insights into the design’s performance, functionality, and ergonomics, facilitating iterative improvements and enhancing the overall product development process.

Stage 3: Short Run Manufacturing

For market acceptance and small-scale production, we offer short-run manufacturing solutions. Our SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) technologies provide fast and cost-effective production of high-quality parts. We have collaborated with companies like Vesticam, a leader in infrared video goggles, to successfully produce short-run manufacturing batches. This capability allows you to test the market, conduct clinical trials, and gather valuable feedback before scaling up production.

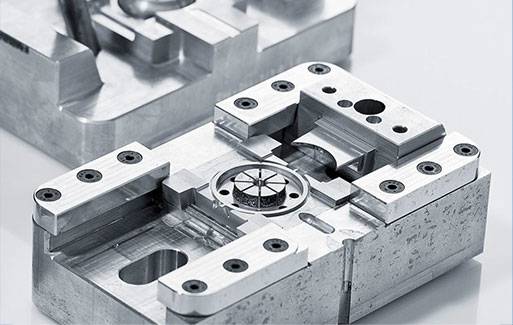

Stage 4: Production

When it’s time for large-scale production, we provide a seamless transition to production processes such as Injection Moulding and Vacuum Casting. These established manufacturing methods ensure consistent quality, efficiency, and scalability for mass production of medical devices. Our expertise in production techniques guarantees that your medical devices meet the highest standards of precision, functionality, and regulatory compliance.

Why Choose Formero?

Formero is your trusted partner for medical device development. With our comprehensive solutions, advanced technologies, and dedicated team of experts, we are committed to delivering exceptional results. From concept to production, we work closely with you to ensure the success of your medical device projects. Contact us today to discuss your medical device development needs and experience the Formero advantage.

Ready to speak with us?

If you have questions please feel free to contact us.